SQ(G) Industrial Cobalt-60 Irradiation Facility

1 Introduction

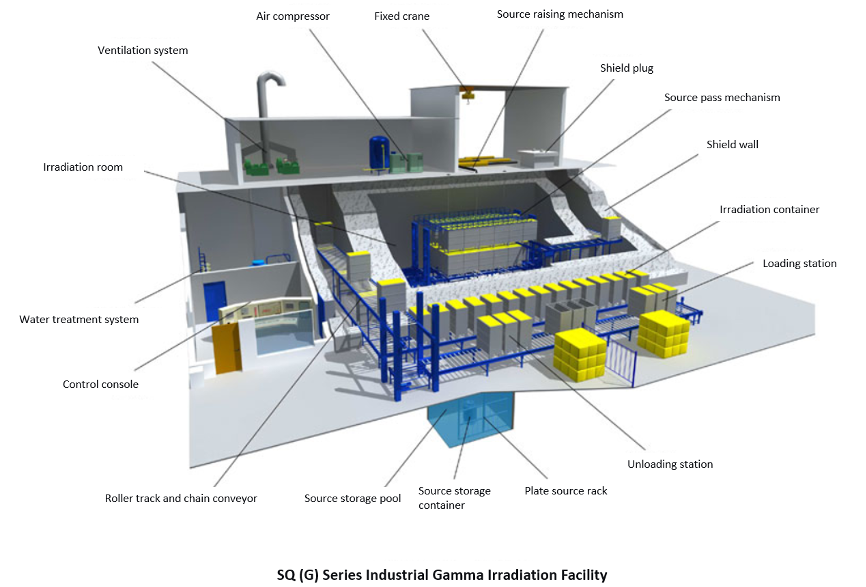

This series of irradiation facilities is primarily designed to meet the irradiation needs of high-density products. The facility utilizes a combined conveying system, including roller conveyors, chain conveyors, and elevators, to transport and irradiate products. Goods are typically loaded on pallets or in containers.

2. Facility Advantages

- Suitable for sterilization of medical supplies requiring high doses and irradiation of high-density products.

- High energy utilization efficiency, low product dose uniformity ratio, and high load capacity.

- Flexible operation modes, enabling layer changing, side changing, and internal circulation within the irradiation chamber.

- Simple equipment structure, easy maintenance, and low failure rate.

3. Technical Features

- Source Rack: Utilizes a plate source rack for bare source loading, offering large capacity and high energy utilization efficiency.

- Conveying System: Employs a source-passing mechanism combining roller conveyors and elevators, capable of dense, multi-channel, multi-station operation. It can automatically change layers and sides within the irradiation chamber or perform multi-loop operation.

- Barcode System: Uses a barcode system to monitor and manage irradiated products, ensuring traceability.

- Control System: Utilizes Siemens PLC programmable logic controllers and WinCC data acquisition and management software.

- Safety Interlock System: Designed with comprehensive multiple, multi-level safety interlock measures, fully complying with Chinese national standards and IAEA safety requirements.

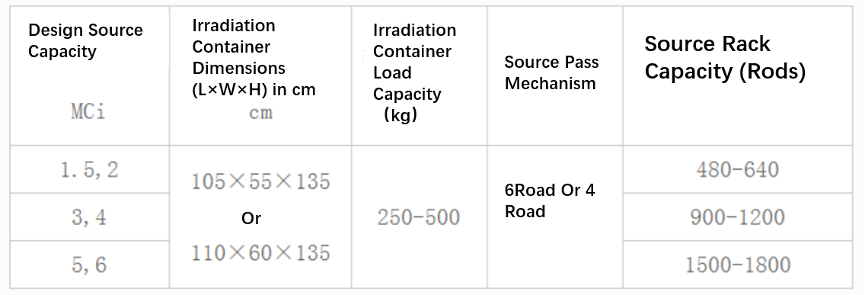

4. Main Parameters