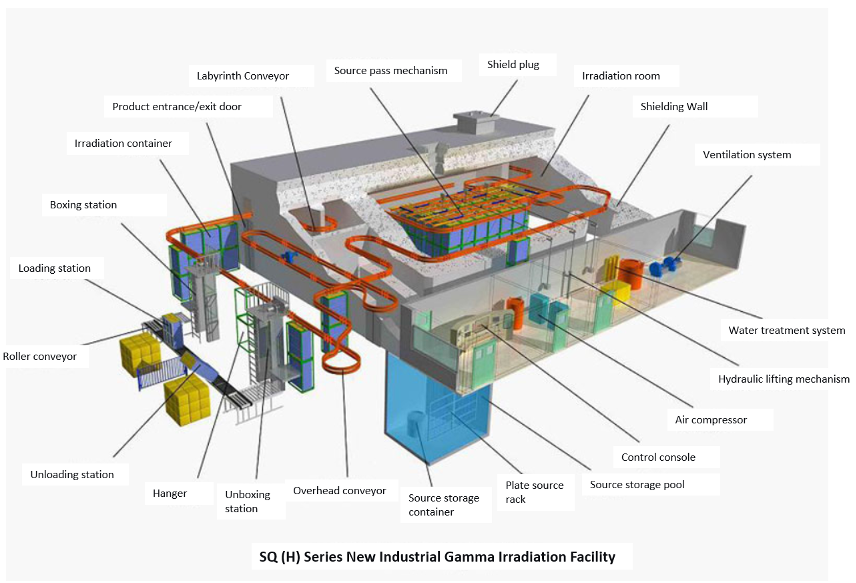

SQ(H) Industrial Cobalt-60 Irradiation Facility

1 Introduction

With the rapid development of China's economy, the demand for large-scale cobalt-60 irradiation facilities has significantly increased. Before 2000, irradiation facilities in China were mostly static types with capacities of 300,000 to 500,000 curies or below, with only a few facilities reaching 1 million curies or more. These existing facilities can no longer meet current demands. In response, we initiated the research and design work for the large-scale, safe, efficient, and multifunctional new SQ(H) series industrial gamma irradiation facility in 2001. Considering international trends in radiation processing and China's specific conditions, we incorporated innovations into the design and conducted extensive testing, ultimately completing the design and obtaining six patents for this facility. This facility can be widely applied for the disinfection and sterilization of medical supplies, food, and Chinese patent medicines.

The SQ(H) series new industrial gamma irradiation facility has gained favor from numerous enterprises in China's radiation processing industry due to its novel design, stable performance, safety, reliability, and numerous other advantages. Currently, these facilities have been built and are operational in locations such as Suzhou, Nanjing, Wuxi, Zhangjiagang, Nantong, Beijing, and Lanzhou in China. Furthermore, facilities are under construction in Beijing, Nanjing, Tianjin, Yantai, among others, and are expected to be operational by the end of 2006. Our company is currently undertaking the design, supply, installation, and commissioning tasks for a 6 MCi irradiation facility abroad. The total designed source loading capacity for the completed and under-construction facilities mentioned above has reached 1.1 × 10^18 Bq (29.5 million curies), making it the preferred and mainstream choice for new irradiation facilities in China and highly regarded by international experts.

This facility boasts a high degree of modernization, making it very easy to obtain relevant domestic and international certifications. The already completed facilities have obtained TUV or FDA certifications. Precisely because of the excellent performance of the completed projects, many international radiation processing experts or clients have given very high evaluations after visiting and certifying the facilities of Suzhou Zhonghe Huadong Irradiation Co., Ltd., and have expressed willingness for cooperation.

In summary, the SQ(H) series new industrial gamma irradiation facility possesses notable characteristics such as safety, high efficiency, and multifunctionality. Its design is successful and fully meets the needs of current large-scale industrial radiation processing. The following sections detail its advantages, specific performance, and design features.

2. Product Advantages

2.1. Safe, Reliable, and Low Cost

- Shield design utilizes the mature international point kernel integration shielding calculation program QAD-CG and the "Monte Carlo method" recommended by ICRP and widely used worldwide, using ordinary concrete as the shielding material, resulting in good shielding effect and low cost.

- All safety protection measures meet or exceed the requirements of IAEA Safety Series No. 107 "Radiation Safety of Gamma and Electron Irradiation Facilities" and IAEA Safety Series No. 115 "International Basic Safety Standards for Protection Against Ionizing Radiation and for the Safety of Radiation Sources" (BSS).

2.2. High Efficiency and Low Mechanical Failure Rate

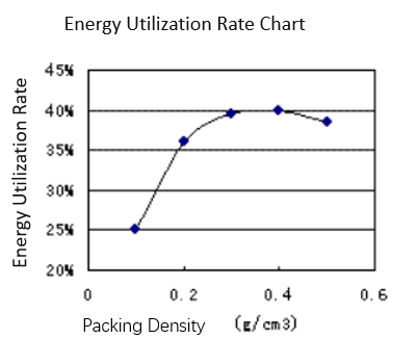

- Energy utilization efficiency can be higher than 40%.

- High-standard, high-quality products are used for important components and elements, ensuring a system failure rate of less than 1%.

- Minor faults can be addressed without stopping operation, enabling annual operation time to exceed 8000 hours.

2.3. High Automation and Low Operating Cost

- Advanced automated loading and unloading mechanisms significantly improve work efficiency and save labor.

- Automatic side changing of goods is achieved within the irradiation chamber, and automatic layer changing is achieved outside the irradiation chamber.

- Programmed control and network management not only reduce the impact of human factors and ensure uniform product quality but also save a significant amount of manpower, resulting in lower overall operating costs for the facility.

2.4. Large Output and High Processing Speed

High energy utilization efficiency (>40%); based on automatic side and layer changing, the arrangement scheme of cobalt sources on the plate source rack is optimally selected, resulting in a good dose uniformity ratio. Simultaneously, the facility has a large source loading capacity, leading to high product processing capability. The use of pneumatic source-passing mechanisms within the irradiation chamber maximizes the product processing speed.

2.5. Personalized Design

According to the needs of specific regions and markets, optimal design of the irradiation container and source arrangement allows the facility to maximally conform to requirements and enhance its production capacity.

2.6. Flexible Operation Modes

- The facility can achieve multiple operation modes according to customer needs, fully meeting various requirements.

- Users can flexibly choose between source-overlap or product-overlap modes based on their needs.

- Capable of irradiating more than two types of products simultaneously.

2.7. User-Friendly Human-Machine Interface

All operation interfaces are graphical interfaces, and various reports can be provided according to customer needs.

3. Product Performance

3.1. Large Source Loading Capacity:

Different source loading capacities can be designed according to customer requirements, with a maximum single-unit design capacity of 2.22 × 10^17 Bq (6 MCi), fully meeting the demands of industrial production.

3.2. High Energy Utilization Efficiency:

Energy utilization efficiency can reach 30%-40%, see Figure 1.

Figure 1. Energy Utilization Efficiency

3.3. Good Uniformity Ratio:

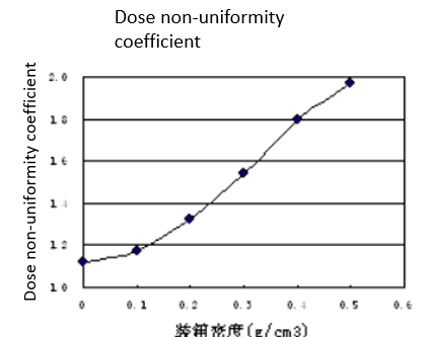

The dose uniformity ratio can reach 1.2 - 1.4 (for product density 0.1 - 0.2 g/cm³). Even for high-density products (0.4 - 0.5 g/cm³), the uniformity ratio can be guaranteed to be better than 2. See Figure 2.

Figure 2. Dose Uniformity Ratio

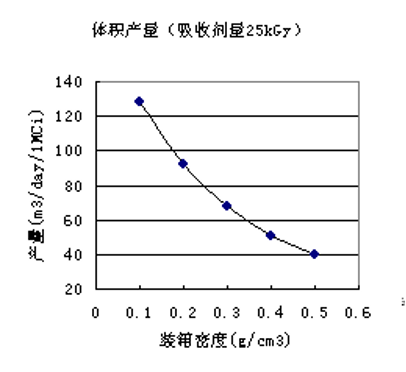

3.4. High Processing Capacity:

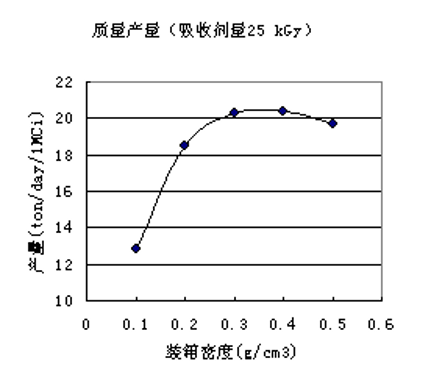

Due to the large source loading capacity, high energy utilization efficiency, and good uniformity ratio, the processing capacity of this facility is greatly enhanced. See Figures 3 and 4.

Figure 3. Volumetric Output

Figure 4. Mass Output

3.5. Wide Range of Product Densities and Dose Requirements:

Density range 0.1 - 0.5 g/cm³; capable of both high-dose irradiation and meeting some low-dose irradiation needs simultaneously.

3.6. Automatic Layer and Side Changing:

Reduces uncertainties associated with manual layer and side changing, benefiting irradiation uniformity.

3.7. Multiple Safety Interlocks:

Including passage doors, infrared sensors, pull-wire switches, dose monitoring, source position indication, etc.

3.8. Flexible Operation Modes:

Multiple operation modes can be designed to meet users' specific needs.

4. Product Innovations

4.1. Source Rack

- Utilizes a single-plate, multi-door test-tube rack structure, which is simple, extremely convenient for loading/unloading source rods, has large source loading capacity, and facilitates optimal re-combination and arrangement of old and new sources.

- Directly loads bare sources, helping to improve source energy utilization efficiency.

- Capable of automatic source lowering upon power loss; the source rack operates smoothly during raising and lowering.

4.2. Product Conveyance and Accumulation System

- Ingeniously combines pneumatic source-passing mechanisms with electric power-and-free overhead conveyors (for maze conveyance and loading/unloading sections). Converts the forward rotation and side-changing movement of irradiation containers within the irradiation chamber into translational movement for side-changing, ensuring smooth, safe, and reliable operation.

- Novel structure, high technical level, capable of multi-channel, multi-station, densely arranged irradiation. The source-passing mechanism part can achieve 6 lanes (outer 4, inner 2) or mixed lanes for continuous automatic operation, realizing comprehensive multi-purpose, multi-product irradiation in one machine.

- The source-passing mechanisms are arranged tightly; the inner 2 lanes in the mechanism are close to the center of the source plate, and the distance between lanes is small, resulting in high source energy utilization efficiency. Irradiation containers use aluminum alloy structure and can accommodate various operation modes like source-overlap automatic side-changing and product-overlap automatic layer changing and side-changing.

- Flexible and convenient operation, capable of simultaneously irradiating products with different absorbed doses, each automatically entering and exiting according to pre-set programs.

4.3. Automatic Loading/Unloading and Layer Changing Device

Performing layer changing outside the irradiation chamber allows minor mechanical faults during the process to be resolved promptly without stopping operation, significantly improving facility availability. This mechanism has been proven accurate and reliable through testing and operational experience.

4.4. Programmed Control and Network Management

- Uses Siemens PLC programmable logic controllers to control facility operation and ensure operator safety.

- The control room is equipped with an upper-level computer for real-time monitoring of the production process, dynamic screens, and printing production data reports. The control console has a simulated operation diagram of the overhead conveyor system and relevant signal alarm lights.

- Uses a barcode identification system to monitor irradiated goods. This system consists of handheld barcode management systems and barcode monitoring systems, enabling automatic recording and tracking of product information and ensuring traceability of customer products.

- Provides network interfaces, enabling modern management through connection with the company's network system.

- Friendly human-machine interface facilitates staff operation.

4.5. Industrial TV Monitoring System

The industrial TV monitoring system allows real-time monitoring of the irradiation chamber interior, operation hall, warehouse, main control room, etc., enabling company supervisors to understand the operation status of the irradiation facility online.

The use of reflective stainless steel mirrors and radiation-resistant lenses within the irradiation chamber significantly extends the service life of this system.